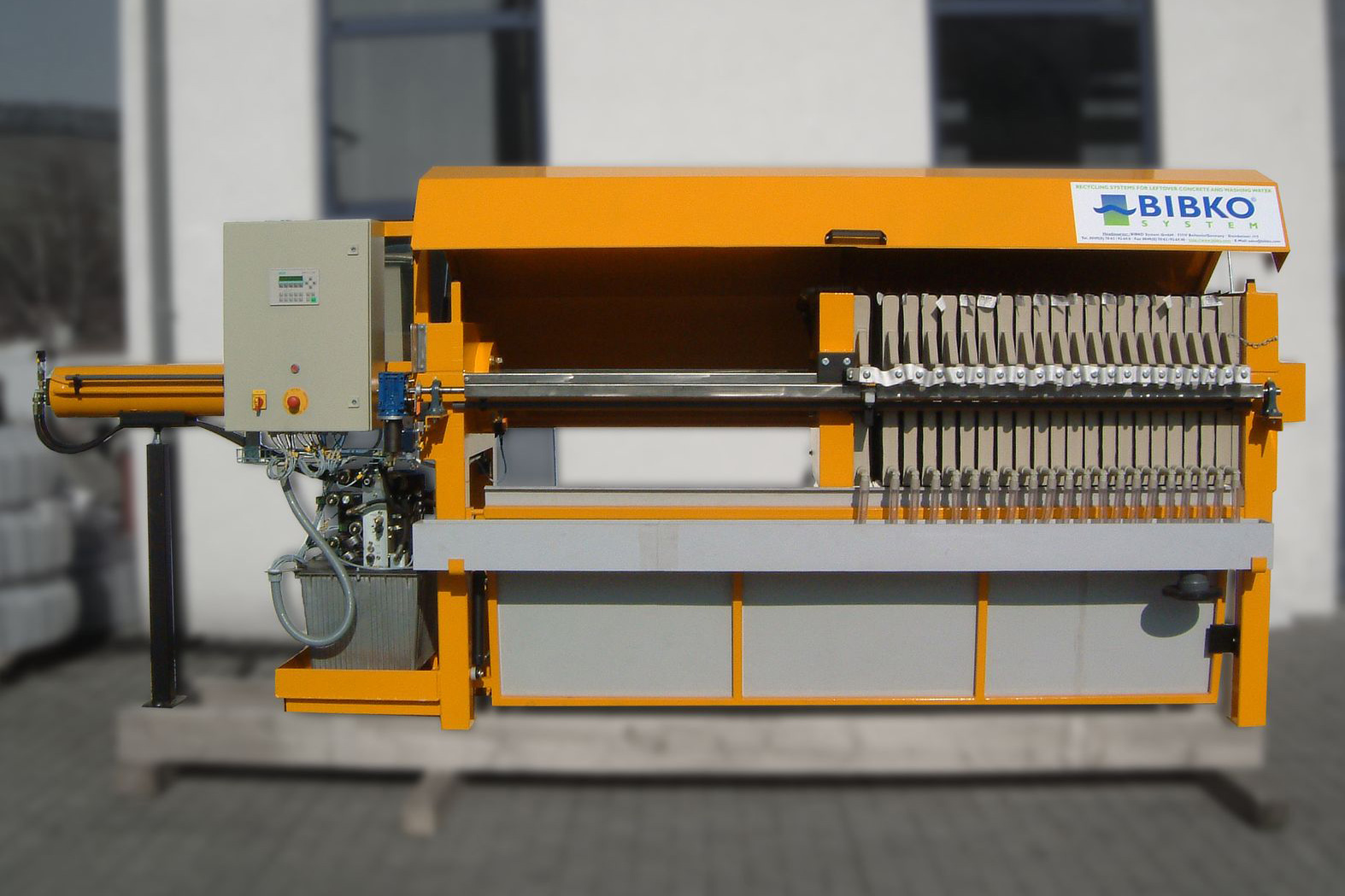

ClearPress Chamber filter press for purification (filtration) of residual/wash water with bindable fine particles (cement).

Residual water and wash water can be purified with a ClearPress Chamber filter press. Here, the fine particles in the residual and wash water are removed, so that purified water is available after the process. With all processes, the residual or wash water is supplied to the filter press either directly or from an agitator tank. The pH value can also be reduced from 11 to 13 by further treatment of the purified water.

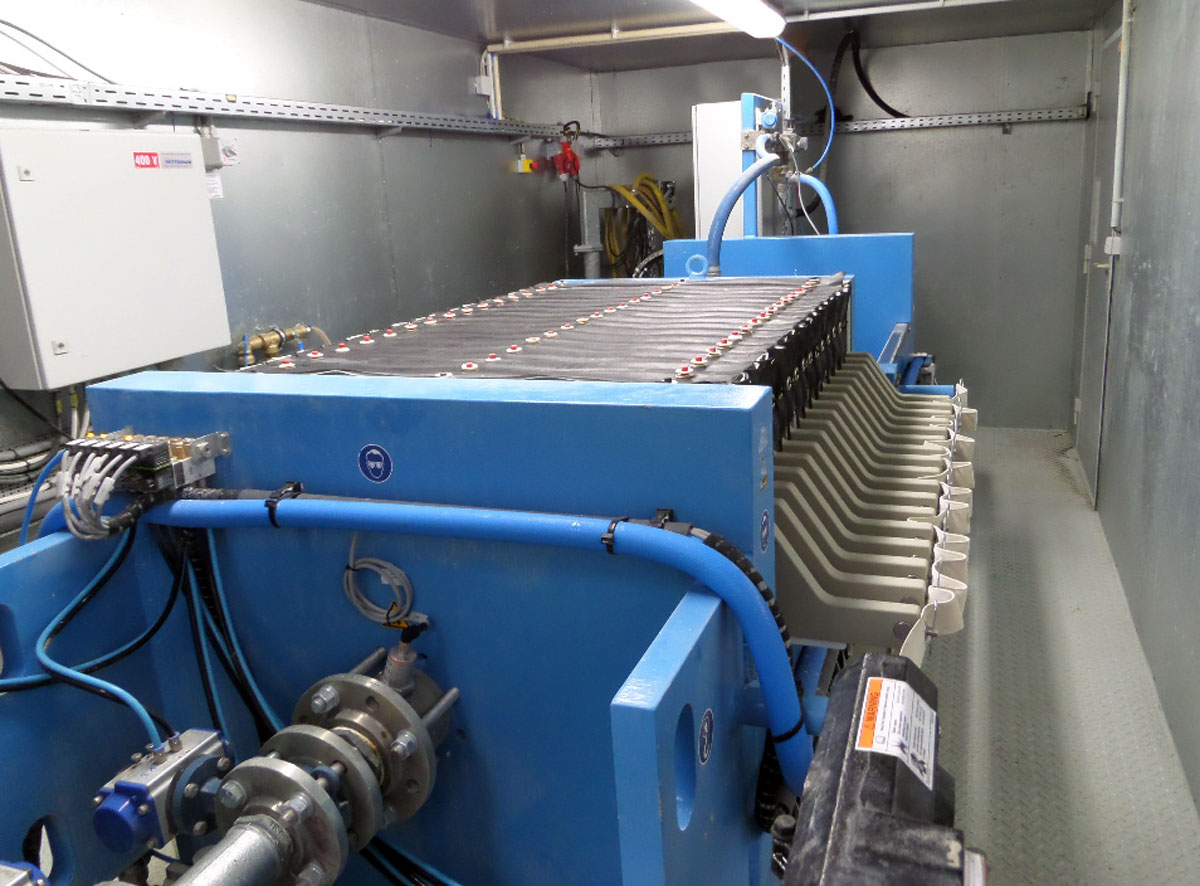

Using a ClearPress Chamber filter press, residual/wash water can be filtered down to a few μm The press consists of several filter plates arranged in a row. The plates are enclosed by a filter cloth that retains the coarse particles. During the operation of the ClearPress Chamber filter press, the filter plates are compressed under high pressure, and the residual/wash water flows between the plates from the inside out. Here, the fine particles contained are separated. A filter cake forms.

The filtered water can be used in two ways:

- Storing the clear water in a clear water tank for mixing new concrete

- Reducing the residual water density in the agitator tank to a desired value

Once the chambers are completely filled with filter cake, the cake is removed. The filtered water is collected and flows into a buffer tank.

The resulting filter cake is either disposed of or reused (e.g. as filling material for road construction). The purified water collected in the buffer tank can be reused in the production cycle.

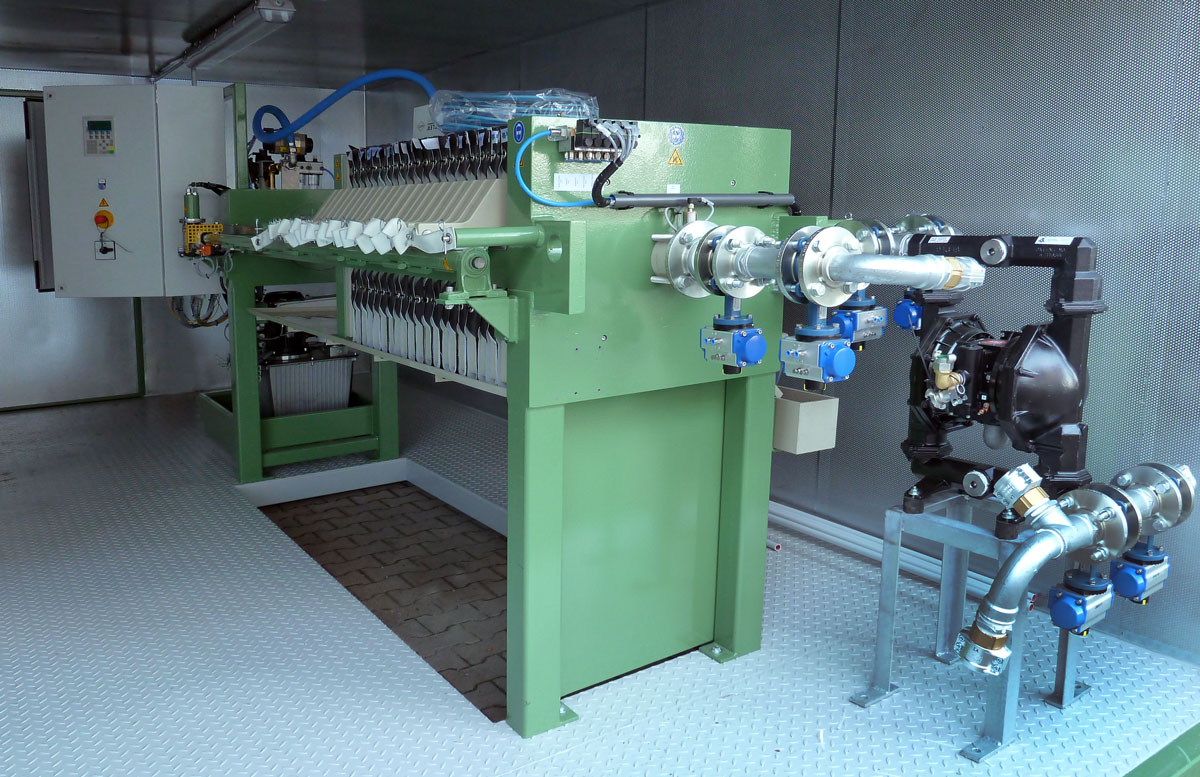

A container enclosure allows the ClearPress Chamber filter press to be housed safely during the winter. The housing itself is isolated to enable smooth operation in winter. For even better protection against the cold, the discharge opening can be equipped with an automatic closing flap.

The technical advantages of the ClearPress Chamber filter press at a glance

- Purification of residual/wash water with fine particles (cement) that have binding properties

- Purification of coloured water

- The water content in the filter cake is only approx. 25 % (watertight)

- Simple handling of the filter cake

- Little space required, high filtration performance of the system

- Low assembly costs

- Low operating and maintenance costs

The economic advantages of the ClearPress Chamber filter press at a glance

- Reduction of water costs by reusing the filtered water

- for the production of concrete

- for surface treatment (e.g. concrete blocks, paving stones)

- for cleaning mixers, bucket conveyors

- Avoidance of wastewater charges and waste disposal costs

Furthermore, the BIBKO® ClearPress Chamber filter press can be equipped and supplied with the following options:

- Different isolated containers with stair case as winter-proof enclosure

- Automatic closure of filter cake discharge opening to avoid danger of frost in winter

- Densimeter

- Automatic acidification of the filter cloths

- pH neutralization

- Residual water basin and clear water basin

- Mobile systems